Best Laser Cutting Machines for Your Workshop

In the ever-evolving world of manufacturing and design, laser cutting machines have become indispensable tools, revolutionizing the way we approach precision cutting and engraving tasks. These machines harness the power of concentrated laser beams to cut through various materials with unmatched accuracy, speed, and efficiency. The versatility and precision of laser cutting machines make them crucial assets in large-scale industrial applications or small-scale creative projects. This article aims to guide you through the different types of laser-cutting machines, highlighting their unique features, advantages, and typical applications. We’ll also review some of the top laser cutters of 2024, taking an in-depth look at their key features, performance, and pricing. By the end of this guide, you will have a clearer understanding of how to choose the best laser cutting machine tailored to your needs. CO2 laser cutting machines utilize a carbon dioxide gas mixture that is electrically stimulated to produce a laser beam. These machines are widely used for cutting non-metallic materials such as wood, acrylic, fabric, and certain plastics. Description and Common Uses: CO2 lasers are popular for their ability to cut and engrave a wide variety of materials. They are commonly used in industries such as signage, woodworking, and fashion due to their precision and clean cutting edges. Advantages: Disadvantages: Fiber laser cutting machines generate laser beams using optical fibers doped with rare earth elements. These machines are particularly effective for cutting metals, including stainless steel, aluminum, brass, and copper. Description and Common Uses: Fiber lasers are known for their high-speed cutting and energy efficiency. They are commonly used in the automotive, aerospace, and electronics industries where precision metal cutting is essential. Advantages: Disadvantages: Key Features and Applications: Triumph Fiber Laser Cutter is designed for industrial metal cutting applications. It boasts high-speed cutting, precision, and the ability to handle reflective metals like aluminum and copper. Price and Performance Review: With a higher price point, Triumph provides robust performance suitable for heavy-duty industrial tasks, offering excellent value for large-scale operations. Key Features and Applications: Amada Laser Cutters are renowned for their advanced technology and robust construction, designed to handle a wide range of materials including steel, aluminum, and titanium. They offer high precision and efficiency, suitable for automotive, aerospace, and industrial manufacturing. Price and Performance Review: Amada's laser cutters come with a premium price tag, reflecting their top-tier performance and durability. They are ideal for businesses that require consistent, high-quality cuts for large-scale production. Key Features and Applications: Bystronic Laser Cutters are known for their versatility and user-friendly interfaces. These machines can process various materials, including thick metals, with high accuracy. They are widely used in sheet metal processing, machinery manufacturing, and metal art. Price and Performance Review: Bystronic offers a range of models to suit different budgets, with performance levels that justify their cost. They provide excellent cutting speed and reliability, making them a cost-effective choice for many businesses. Key Features and Applications: Prima Power Laser Cutters excel in automation and flexibility, designed for both small and large production runs. Their machines can handle complex shapes and fine details, suitable for the automotive, electronics, and appliance industries. Price and Performance Review: Prima Power offers competitive pricing with advanced features that enhance productivity. Their machines are a solid investment for companies looking to improve efficiency and precision in their operations. Key Features and Applications: ADH Machine Tool offers a variety of fiber laser cutting machines, including single table, double table, and dual-use models for cutting both plates and tubes. These machines are designed for high-speed and precision cutting of metals such as carbon steel, stainless steel, aluminum, and copper. Price and Performance Review: ADH provides cost-effective solutions with a focus on high quality and reliable performance. Their machines are competitively priced, offering robust features and support, making them a great choice for businesses of all sizes. The precision laser cutting machine, in particular, is ideal for cutting thin non-ferrous and precious metals, offering a unique advantage in industries requiring detailed and delicate work. When selecting a laser cutting machine, understanding the power requirements is crucial. Laser cutters come in various wattages, each suitable for different materials and cutting depths. Higher wattage lasers, typically above 100W, are ideal for cutting thicker materials and metals. Lower wattage lasers, around 40W to 60W, are suitable for engraving and cutting thinner, non-metallic materials like wood, acrylic, and fabric. It's essential to match the machine's power to your specific needs to ensure efficiency and precision. Different laser cutting machines are optimized for different materials. CO2 lasers are versatile and can cut non-metallic materials like wood, acrylic, and textiles. Fiber lasers are best for cutting metals such as stainless steel, aluminum, and copper, offering high precision and speed. Assessing the materials you will primarily work with will help determine the type of laser cutter you need. The bed size and work area of a laser cutting machine dictate the maximum dimensions of the material you can work with. For large-scale projects, a machine with a larger bed size is essential. This allows you to cut bigger pieces without the need for repositioning, saving time and ensuring accuracy. Conversely, for smaller projects or detailed engraving work, a smaller bed size may be sufficient. Consider the typical size of your projects when selecting a machine to ensure it meets your requirements. User-friendly software and advanced control systems are vital for optimizing the performance of your laser cutting machine. Many machines come with proprietary software that offers features such as design editing, file importing, and cutting parameter adjustments. Advanced control systems can enhance precision and efficiency, making the cutting process smoother and more intuitive. Ensure the machine you choose has compatible software that meets your needs and is easy to learn and use. Laser cutting machines vary widely in price, from affordable options for hobbyists to expensive industrial-grade machines. Establishing a budget before purchasing is essential. Consider the initial cost of the machine, as well as potential maintenance, software, and accessory expenses. It's also important to evaluate the machine's value in terms of performance, durability, and the support provided by the manufacturer. Investing in a high-quality machine can save money in the long run by reducing downtime and repair costs. Laser cutting machines are used across a multitude of industries due to their precision, efficiency, and versatility. Here are some key sectors where laser cutting is integral: Beyond industrial applications, laser cutting machines are popular in educational and hobbyist settings. Here’s how they are utilized: Yes, some laser cutters can cut metal, but it depends on the type of laser and its power. Fiber lasers and high-power CO2 lasers are typically capable of cutting various metals, including stainless steel, aluminum, and copper. For thicker metal sheets or more complex cutting, industrial-grade fiber lasers are recommended. Common materials include wood, acrylic, leather, fabric, paper, and certain plastics. However, CO2 lasers are not suitable for cutting metals unless they are of very high power and are designed specifically for such tasks. They are also not recommended for cutting PVC or other materials that release toxic fumes when heated. The precision of laser cutting machines is one of their key advantages. High-quality laser cutters can achieve extremely fine details with tolerances as tight as 0.001 inches (0.025 mm). The precision depends on factors such as the quality of the laser beam, the stability of the machine, and the accuracy of the motion control system. When choosing the best laser cutting machine, we discussed various factors including cutting precision, speed, suitable materials, and cost-effectiveness. By comparing different brands and models, we can see that each machine has its unique advantages and application scenarios. Whether for industrial production or personal creation, finding the machine that best suits your needs is crucial. As a laser cutting machine manufacturer with over 20 years of experience, ADH Machine Tool is dedicated to providing high-quality, high-performance laser cutting equipment, like single table fiber laser cutting machines, double table, dual-use, dual-use with covers, tube laser cutting machines, precision laser cutting machine. I invite you to click on our product page to learn more about our products and discover how we can help grow your business. Laser Marking Machine,High Speed Laser Marking Machine,Food Packaging Bag Laser Marking Machine,Uv Laser Marking Machine Herolaser , https://www.hclaserwelding.comI. Introduction

II. Types of Laser Cutting Machines

1. CO2 Laser Cutting Machines

2. Fiber Laser Cutting Machines

3. CO2 VS. Fiber Laser Cutting Machine

Aspect CO2 Laser Cutting Machines Fiber Laser Cutting Machines Laser Generation Uses a gas mixture (predominantly CO2) electrically stimulated to produce the laser beam. Uses optical fibers doped with rare earth elements to generate the laser beam Material Compatibility Best suited for non-metallic materials (e.g., wood, acrylic, fabric, certain plastics). Highly effective for cutting metals (e.g., stainless steel, aluminum, brass, copper) Cutting Speed Generally slower compared to fiber lasers, especially on metals. Faster cutting speeds, particularly on metals. Efficiency Lower photoelectric conversion efficiency, typically around 10-20%. Higher photoelectric conversion efficiency, often over 30%. Maintenance Requires regular maintenance due to the complexity of the gas mixture and alignment of mirrors. Lower maintenance needs, with no need for mirror alignment and fewer consumables. Operating Costs Higher operating costs due to gas consumption and maintenance requirements. Lower operating costs due to higher efficiency and fewer consumables Initial Cost Generally lower initial cost compared to fiber lasers. Higher initial cost due to advanced technology and components. Precision and Edge Quality High precision and smooth edges on non-metallic materials. High precision and smooth edges on metals, with minimal post-processing required. Versatility Versatile for cutting a wide range of non-metallic materials and some metals with special setups. Primarily designed for metal cutting, with limited effectiveness on non-metallic materials III. Top Laser Cutting Machines in 2024

1. Triumph Fiber Laser Cutter

2. Amada Laser Cutter

3. Bystronic Laser Cutter

4. Prima Power Laser Cutter

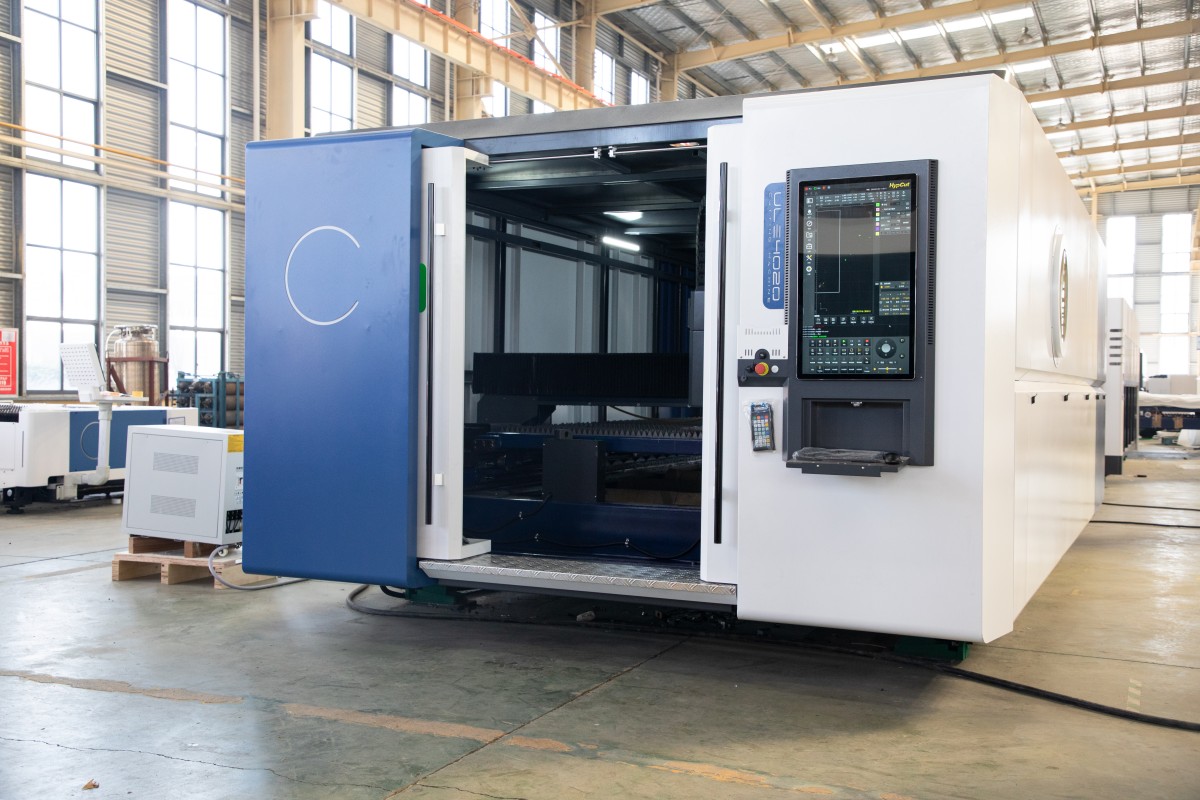

5. ADH Machine Tool Laser Cutter

6. Comparison Table

Brand Key Features and Applications Price and Performance Review Triumph Fiber Laser Cutter - Designed for industrial metal cutting applications

- High-speed cutting, precision, and ability to handle reflective metals like aluminum and copper- Provides robust performance suitable for heavy-duty industrial tasks, offering excellent value for large-scale operations

- Higher price pointAmada Laser Cutter - Renowned for advanced technology and robust construction

- Can handle a wide range of materials including steel, aluminum, and titanium

- High precision and efficiency, suitable for automotive, aerospace, and industrial manufacturing- Ideal for businesses requiring consistent, high-quality cuts for large-scale production

- Premium price tag, reflecting top-tier performance and durabilityBystronic Laser Cutter - Known for versatility and user-friendly interfaces

- Widely used in sheet metal processing, machinery manufacturing, and metal art

'- Can process various materials, including thick metals, with high accuracy- Offers a range of models to suit different budgets

- Performance levels justify their cost

- Provides excellent cutting speed and reliability, making them cost-effective for many businessesPrima Power Laser Cutter - Excels in automation and flexibility

- Designed for both small and large production runs

- Can handle complex shapes and fine details

- Suitable for automotive, electronics, and appliance industries- Offers competitive pricing with advanced features that enhance productivity

- A solid investment for companies looking to improve efficiency and precision in their operationsADH Machine Tool Laser Cutter - Offers a variety of fiber laser cutting machines

- Includes single table, double table, and dual-use models for cutting both plates and tubes

- Designed for high-speed and precision cutting of metals such as carbon steel, stainless steel, aluminum, and copper- Provides cost-effective solutions with a focus on high quality and reliable performance

- Competitively priced, offering robust features and support

- Precision laser cutting machine is ideal for cutting thin non-ferrous and precious metalsIV. How to Choose the Best Laser Cutting Machine

1. Power Requirements

2. Material Compatibility

3. Bed Size and Work Area

4. Software and Control Systems

5. Price and Budget Considerations

V. Applications of Laser Cutting Machines

1. Industry Applications

2. Educational and Hobby Uses

VI. FAQ

1. Can laser cutters cut metal?

2. What materials can a CO2 laser cut?

3. How precise are laser cutting machines?

VII. Conclusion